Eirich at POWTECH TECHNOPHARM 2025: Process solutions “on prescription”

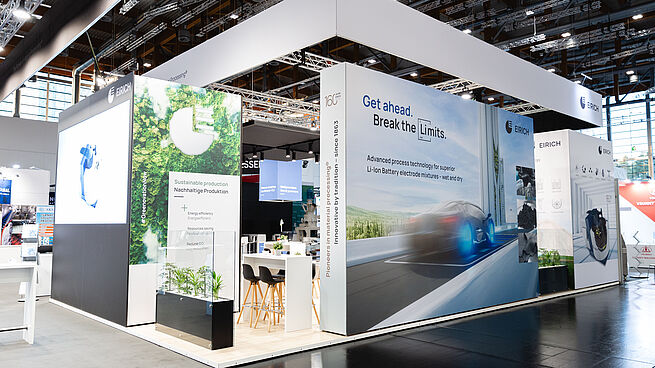

For this year’s POWTECH, the international trade fair for powder, granules, and bulk goods processing technologies, which will take place in Nuremberg from September 23-25, the expert for mixing and preparation technology has come up with a new way to present the company and its innovative process solutions. At the trade show, visitors will be invited to “see the process doctor – a safe pair of hands for acute process problems.” For a live experience at the stand, there will also be real-time demonstrations where visitors can directly observe processes as they take place.

Hardheim, July 10, 2025: Digitalization and automation are fundamentally changing the industrial landscape – particularly in the chemicals, processing, and food industries. Efficiency improvements, sustainability, and environmental awareness have longed ceased being just slogans – nowadays these are standard requirements for modern production processes. Eirich is meeting these challenges with innovative solutions that will not only smooth the path into a digitalized future, but at the same time will also open up more energy-efficient production and make better use of resources thanks to durable and robust preparation technology. Eirich is seizing this opportunity with both hands – in 2022, the company founded the joint venture “prosio vision,” which specializes in the areas of system and process optimization, data handling, and intelligent measuring technology within the Eirich Group.

Interactive “medical practice for processes”

Together with prosio vision, Eirich has converted its traditional trade fair stand into something a little more tongue-in-cheek in the form of a “medical practice for processes” resembling a modern practice with “consulting rooms.” Here, technological know-how is combined with the familiar visual concept of a medical consulting room to convey the many different ways in which Eirich products can be used, with the resulting presentation intuitive and emotive, but also very easy to understand.

This allows process issues that lead to excess reject rates or inefficient workflows to be regarded as “symptoms” that can be treated to optimize the system and keep it healthy. Process monitoring and data collection play the role of a careful, data-assisted “examination,” followed by a comprehensive “diagnosis” via the process analysis and data evaluation. Finally, of course, there is the “treatment” in the form of concrete recommendations for actions, including the use of new machines or retrofitting equipment to lines to provide a long-term boost to efficiency.

A special highlight is the real-time demonstration of the VC1, which provides a unique opportunity to observe the process transparently while it is happening. With the QualiMaster VC1 Eirich offers an intelligent system for continuous product monitoring of bulk materials directly on the conveyor. Equipped with a special camera, the VC1 continuously captures image data of the material, which is then analyzed in real time. This enables contactless in-line measurement of real values such as the particle size distribution, sphericity, or surface structure. This smart system allows precise, autonomous analysis, thereby creating the basis for optimized, stable, and reproducible product quality.

Together with prosio vision as the “data doctor” for process engineering issues, Eirich offers digital solutions for production optimization based on deep process engineering know-how and expertise. Systems for data analysis and process diagnostics help to identify and solve production problems, and as a result the efficiency and sustainability of the line or system can be noticeably improved.

Live demonstration shows off mixer highlights and smart quality control

Of course, there will also be plenty of conventional ways for visitors to immerse themselves in the world of high-quality Eirich technology – including the new R12 for lithium-ion battery production at gigafactory scale or the El1nano, the smallest mixer in the Eirich portfolio and the perfect solution for research applications or for work involving particularly high-quality and expensive raw materials. With CleanLine C5, Eirich will be exhibiting a machine that meets the exacting standards of laboratories in the food and chemical industries for applications in which good hygiene and avoidance of contamination are vital.

Eirich will also be showing off its solutions for one-pot processes, which are made possible by the ability of Eirich mixers to combine a wide range of different tasks in a single unit, such as mixing, dispersing, and drying. This multifunctionality underlines the commercial and environmental advantages that Eirich systems can offer – including space savings, energy efficiency, and flexible recipe applications.

Focusing on growth industries

Rather than just looking at traditional markets, Eirich is rapidly expanding into new and growing markets. Recent additions to the portfolio include the chemicals sector, lithium-ion electrode compounds, and life sciences products such as food products, nutritional supplements, and cosmetics. This diversification manifests the company's competence in the modern process industry across a wide range of different sectors.

“We are really looking forward to POWTECH and to directly meeting industry representatives and our customers. The ever changing challenges drive us to continue our research efforts so that we can keep improving our products and continue to offer our customers future-proof solutions. We will be able to show off the full range of solutions in our portfolio – from laboratory mixers and AI / deep learning offerings to turnkey plants and innovative technologies for the production of electrode mixtures for batteries. As well as our comprehensive milling technology and state-of-the-art preparation systems, we also offer carefully tailored retrofit and service concepts that can be used in existing lines to boost efficiency, sustainability, and service life,” explains CEO Stephan Eirich.