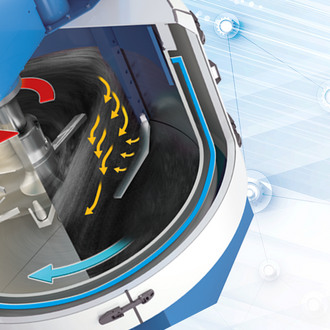

MixSolver® uses far less energy in the production of electrode slurry than a planetary mixer. A planetary mixer consumes around 8,000 kWh of electric energy per day to achieve a daily throughput rate of 20 m3 of slurry, while an Eirich mixer requires just 400 kWh to do the same – a vast cost saving. And this does not even take into account the energy required for cooling, which can be around the same amount again for a planetary mixer but is not required at all for an Eirich mixer. Instead of running 5-9 high-volume planetary mixers in parallel, each of which requires 4-8 hours for a single batch, you can produce the same amount of slurry in one or at most two MixSolvers® in just 30 minutes. In addition, you will also benefit from a huge reduction in floor space requirements, with the Eirich Mixer only needing a third of the space required for planetary mixers.