History & Milestones

1863

Foundation of the first workshop by Gustav Eirich in today's Würzburger Straße in Hardheim.

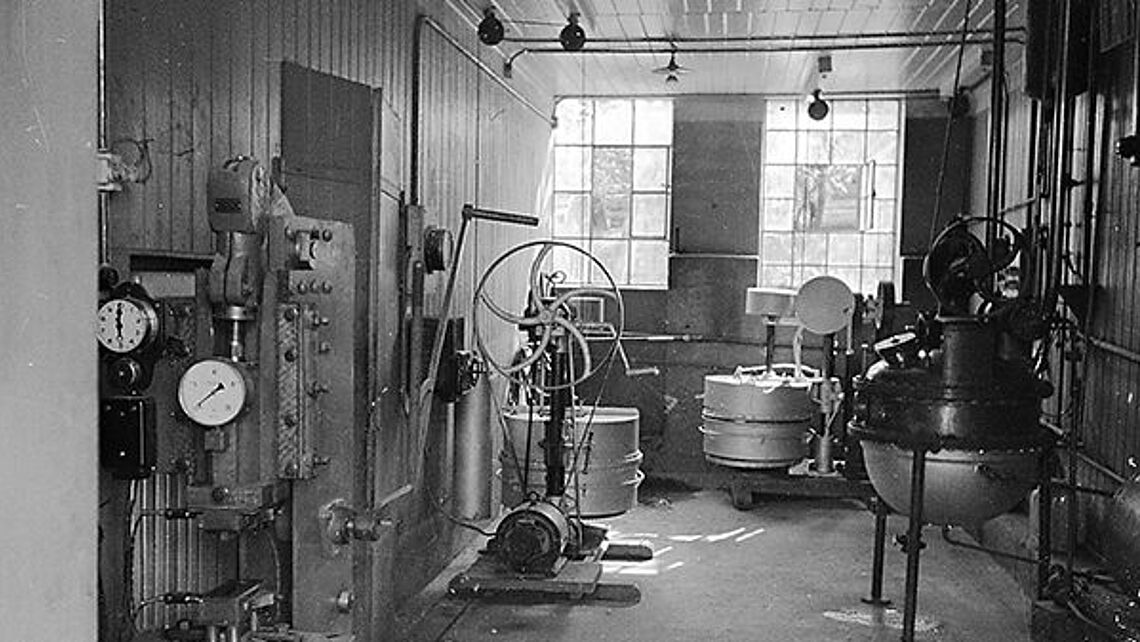

1903

Invention of the first ring trough mixer. This was followed in 1906 by the invention of the planetary mixer by Eirich.

1924

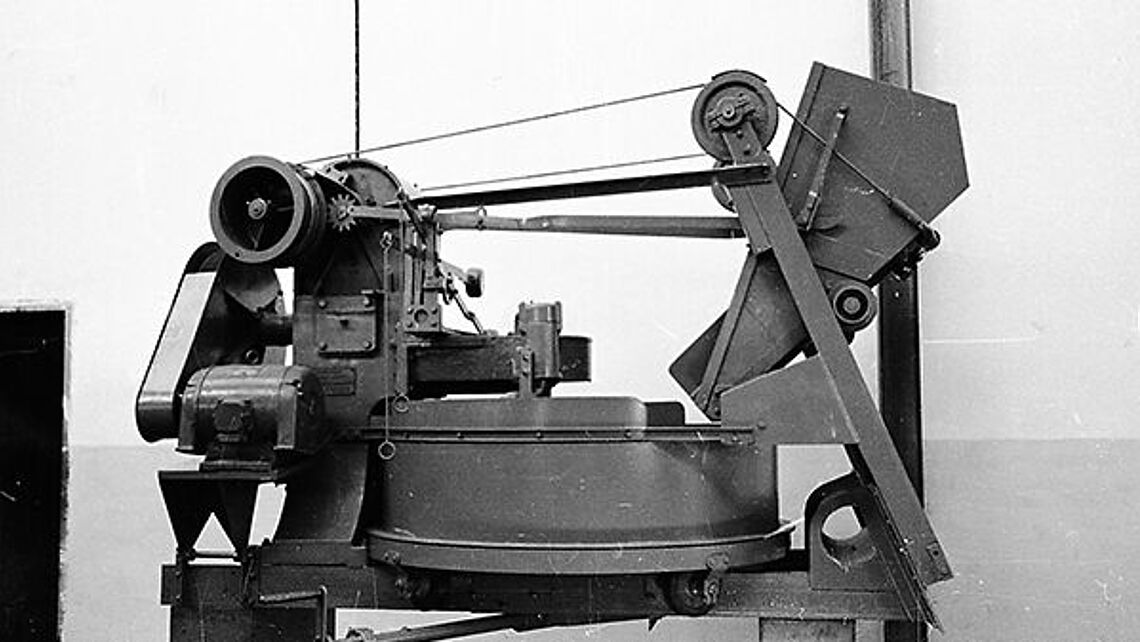

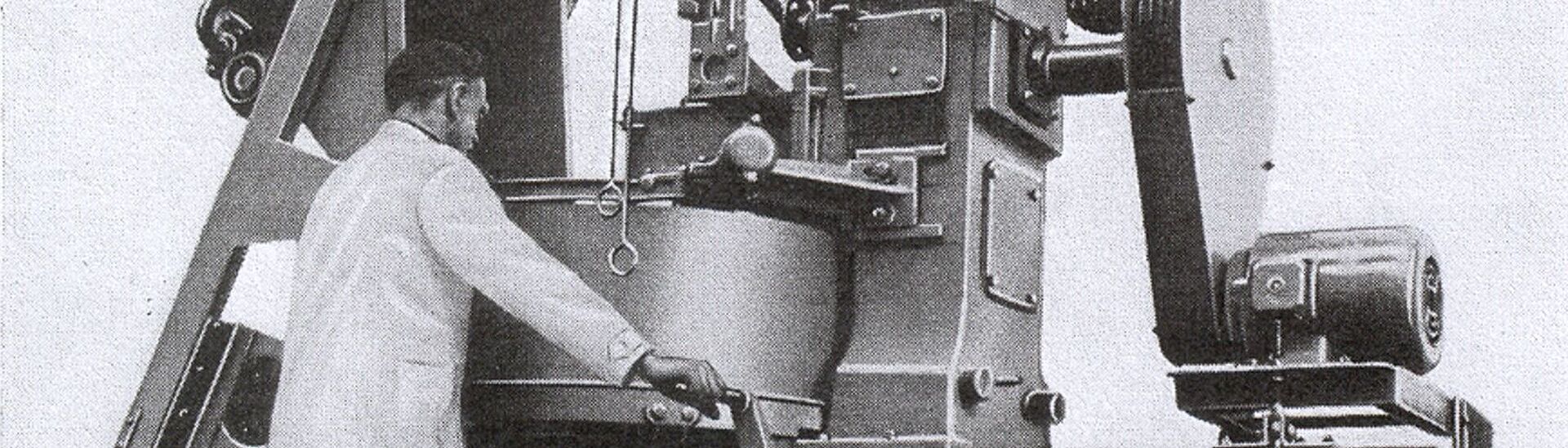

Invention of the Eirich mixing principle: birth of the Eirich counterflow mixer with driven mixing pans.

2024

A 100-year success story with numerous improvements and innovations followed.

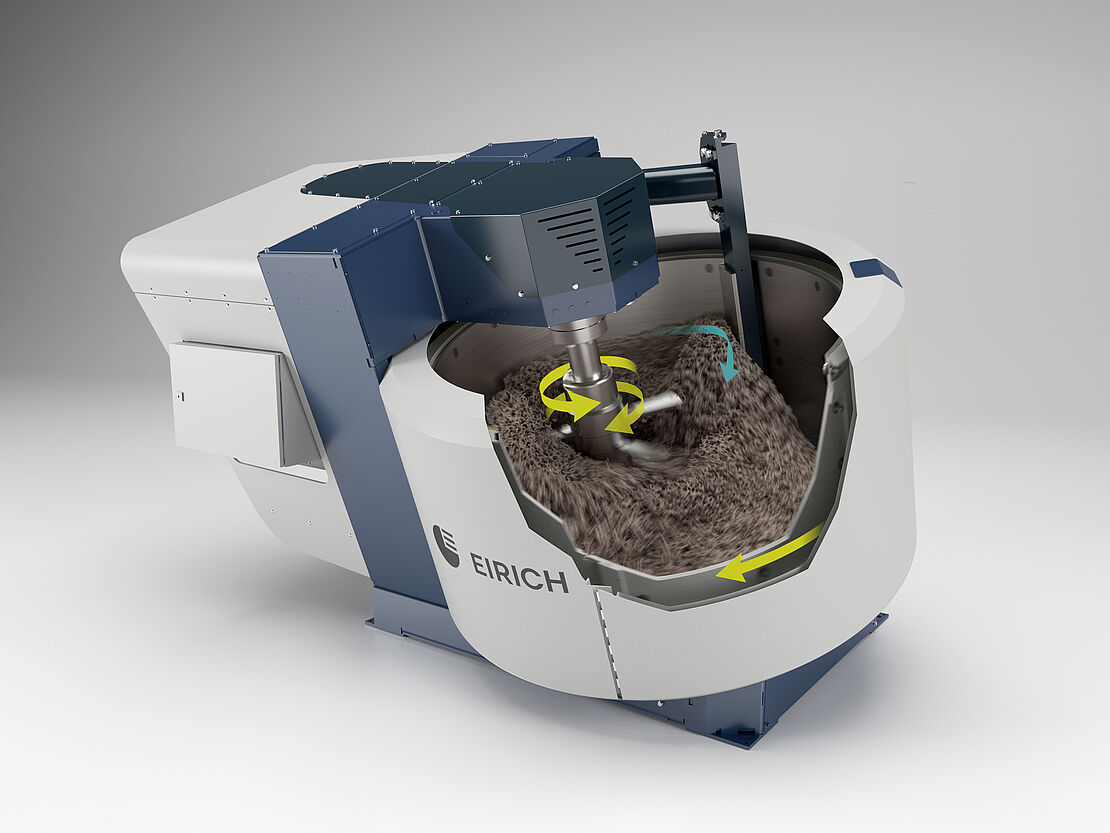

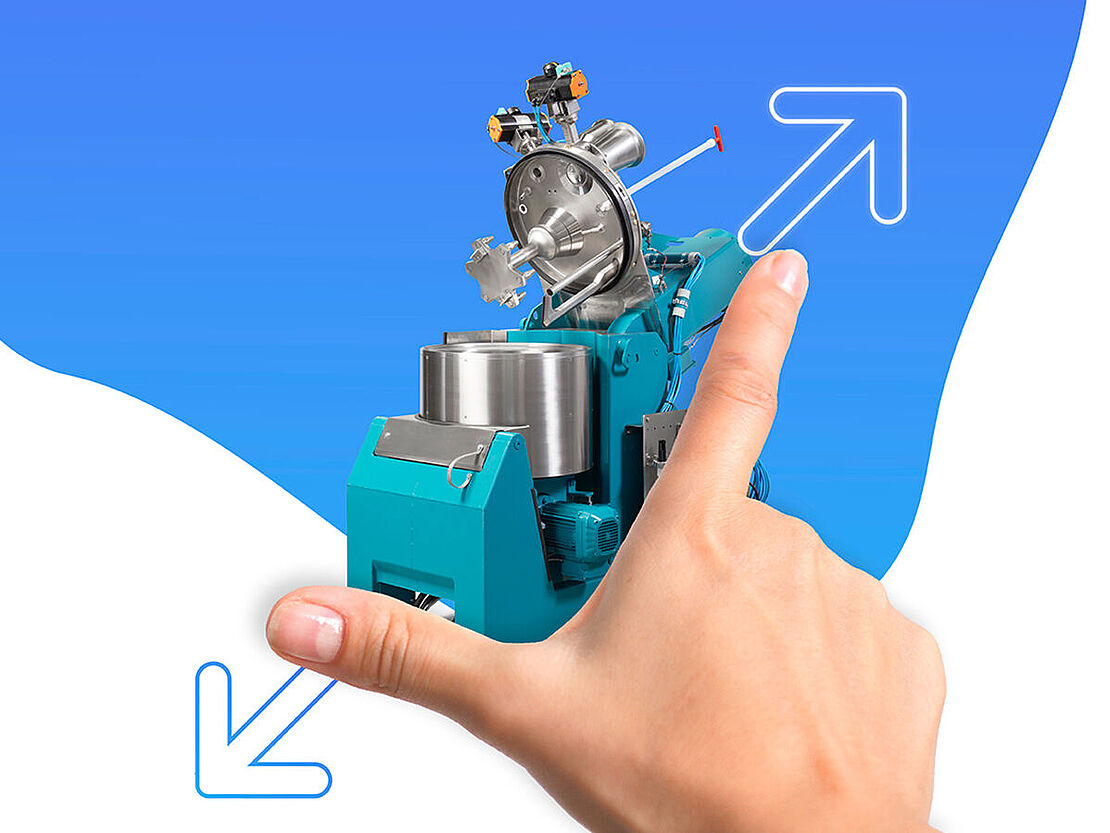

The Eirich Mixing Principle

Eccentrically arranged mixing tool

Component 1

Design, direction of rotation and speed are adapted to the specific application.

Bottom / wall scraper

Component 2

Provides additional shifting, prevents sticking to the wall and bottom and supports emptying.

Rotating mixing pan

Component 3

The rotating mixing pan transports the mix into the area of the mixing tool.

Internationality

Tradition & innovation

Ideas for a whole century

“We are proud of our success and our long existence in such a dynamic market. Eirich proves that tradition and innovation are not mutually exclusive, but build on each other and are an absolute recipe for success when combined.

Many manufacturing companies rely on our technologies and value the longevity of our machines, which have often been in use for decades. We don't want to rest on our laurels, we are constantly developing and, above all, bringing the topic of digitalization into the production halls,” says Ralf Rohmann, Managing Partner of Eirich.

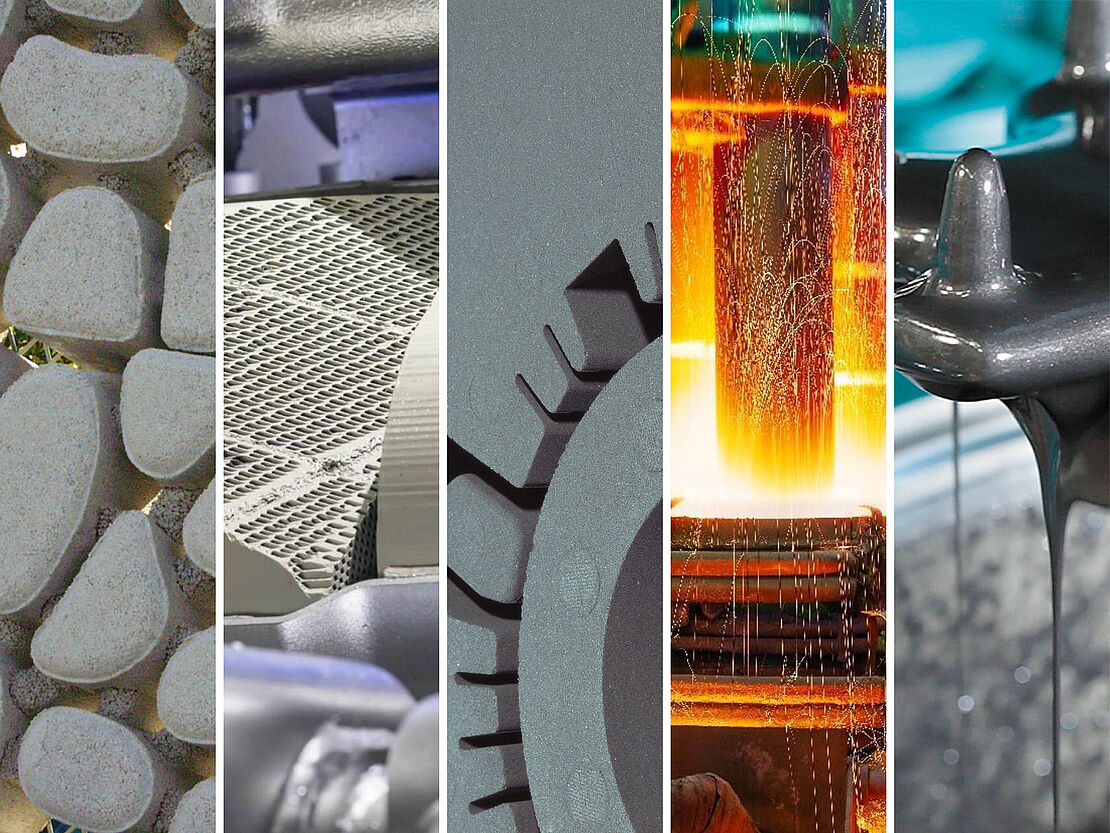

Industries

Important milestones in the development of a wide range of industries and applications are firmly linked to Eirich mixing technology.

The first Eirich mixer from 1903 was initially developed for the then still young concrete industry. Today, the company continues to meet the high demands placed on modern architectural and high-performance concrete in terms of quality and efficiency and is constantly developing its mixing technology. Homogeneity, short batch times, high throughput rates, improved fine distribution and savings on color pigments and binding agents are the result.

The planetary mixer developed in 1906 marked the company's entry into ceramic applications. At that time, the focus was on the production of refractory bricks. The development of the counterflow mixer and the intensive mixer that followed then covered almost all areas of ceramic production as well as the preparation of carbon bodies. Today, the ceramics industry is one of the sectors most affected by rising energy prices and requires innovative solutions. Eirich has therefore developed the EcoPrep® process, which produces a high-quality and economical granulate that is later pressed into tiles or other ceramic products. Compared to conventional technology in spray towers, the process saves up to 60 percent energy as well as raw materials and additives.

Eirich has been a partner to foundries since 1925 with molding sand mixers and offers complete turnkey molding material preparation. Today, in addition to high-quality production results, the industry is also focusing on resource conservation and digitalization. Eirich has developed an intelligent sand management technology that saves raw materials and energy throughout the entire production cycle and also minimizes rejects in the castings. The EVACTHERM® process combines mixing, cooling and bentonite disintegration in one machine under a vacuum atmosphere. The QualiMaster AT1 inline testing device monitors the quality of the molding material in real time and ensures consistently high quality by detecting deviations and taking self-learning countermeasures. Data communication also takes place with the downstream molding system, allowing comprehensive production analyses and predictive molding material compositions.

First trial runs in cooperation with Lurgi (now Metso:Outotec) and distribution of Eirich mixers in iron ore pellet plants in the 1970s. Eirich impressed with a significantly better mixing quality compared to the previous system. Eirich continuous mixers were then the next development stage in the early 1990s for ever higher throughputs, culminating in the DW40 type in 2006 - for the processing of up to 1200 t/h of iron ore concentrate (equivalent to a complete freight train per hour). Eirich was also able to achieve a higher level of processing for sinter mixtures by homogeneously processing significantly higher quantities of fines and ferrous residues. Currently, the development is moving towards the processing of micro pellets which are further processed in the hydrogen-based direct reduction and in the electric arc furnace. In this way, we too can make a major contribution to the decarbonization of the steel industry.

For over 80 years, Eirich mixers have been used for the preparation of battery compounds and have set the pace for lead pasting compounds for lead-acid batteries and depolarization compounds for dry batteries. The machines with heavy kneading kneaders were followed in the 1960s by intensive mixers with high-speed mixing tools. Later, with the introduction of vacuum technology, Eirich provided a highly efficient solution for absolutely homogeneous mixing and gave the industry a major growth spurt. Today, Eirich has established itself as a partner in the production of lithium-ion batteries and offers new resource-saving technologies for development laboratories through to giga-factories.

With Eirich in the lead.

We make our customers better. Analog, digital and personal.

Unique technology

Groundbreaking innovation, high-performance technology and top quality. Our products have been setting standards in process engineering for decades and ensure perfect results. Time after time.

More information

Technology center as a driver of innovation

Happy customers are our motivation: The Eirich Technical Center offers fascinating opportunities for testing, researching and developing the material world of the future. Our experts warmly welcome you.

High-performance products

Eirich machines are something special. Their reliability, quality and durability are unique in the world. Whether mixers, mills, pelletizing plates or entire systems. Eirich is the gold standard for process technology.

More information

Global service network

Customer care is our top priority. With the Eirich Life Cycle Service, worldwide customer service, consulting and staff training, we are always there for our customers when they need us.

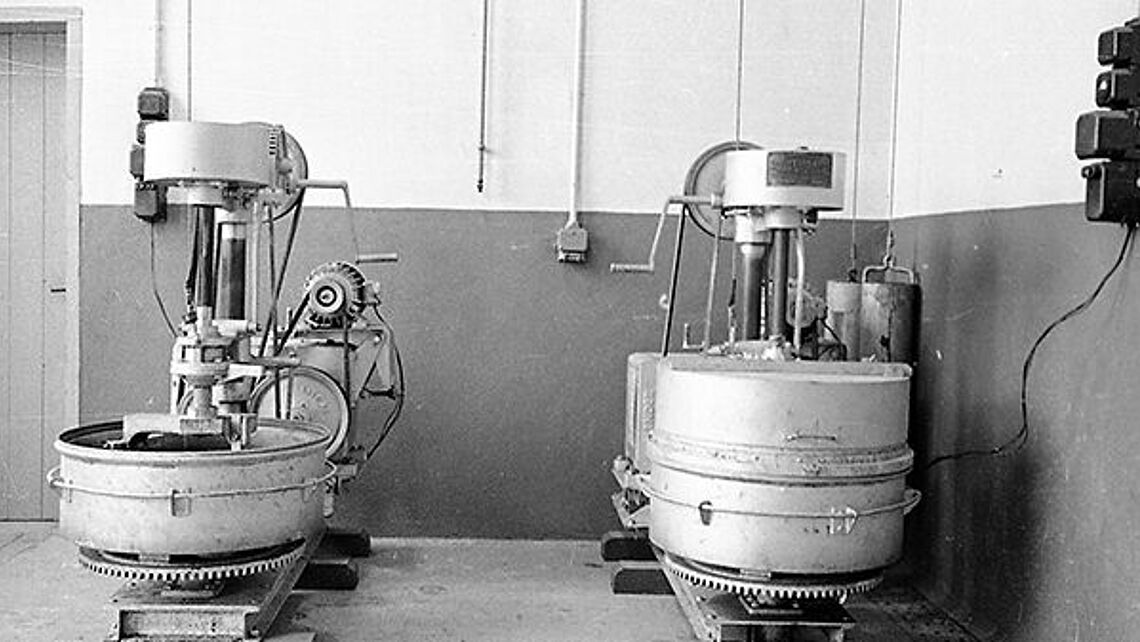

Pioneers then and now

Impressions from the company history