The Eirich world of preparation technology

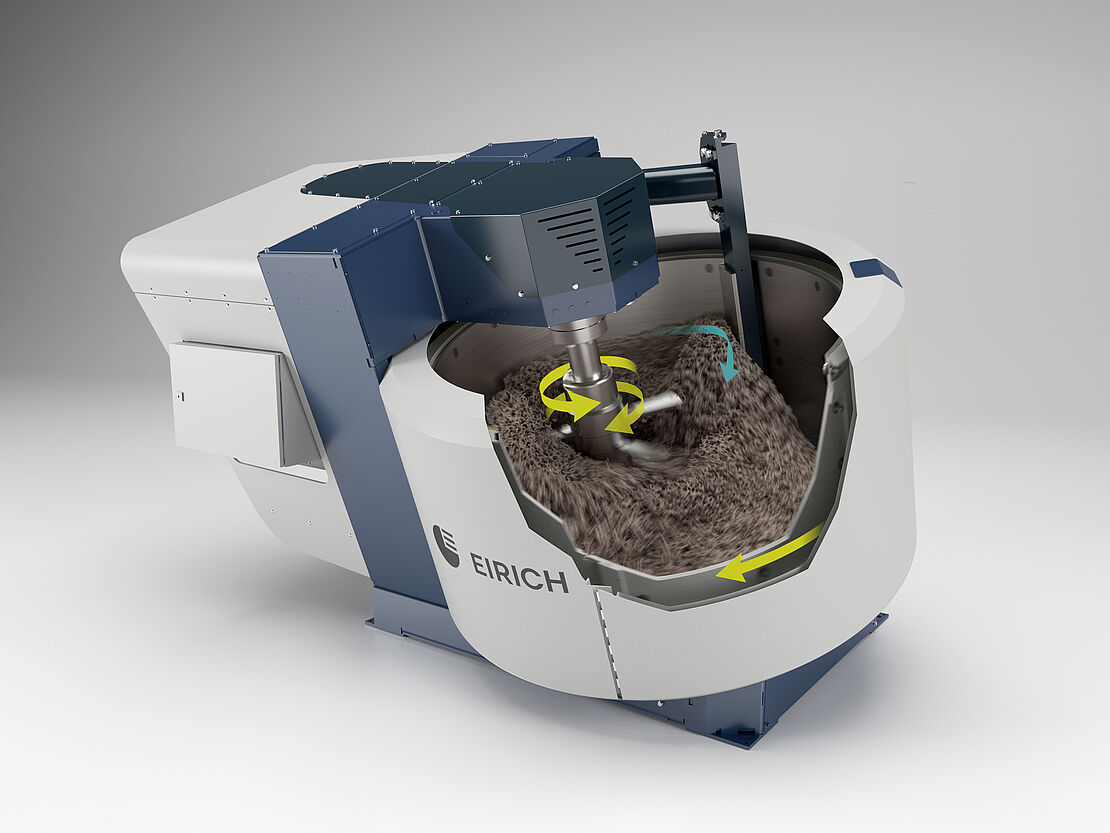

Eirich intensive mixers - the all-rounder for optimum results

Eirich intensive mixers can be used across a broad spectrum of applications in industrial preparation processes in production and the laboratory.

These include mixing, reacting, dispersing, dissolving, slurrying, plasticizing, deaerating, defibering, solubilizing, agglomerating, disagglomerating, pelletizing, granulating, kneading, moistening, drying, heating, cooling, stripping, impregnating, coating, and hydrophobing.

The right mixer for every requirement

Grinding technology - customized and effective

Eirich offers a broad range of mill types with dry or wet grinding for industrial minerals, ores, ceramic raw materials, glass, and fertilizers.

Digital solutions for machines, systems and processes

More efficiency, less wastage

Eirich measurably improves the efficiency of its processes with intelligent digital systems, resulting in less wastage, lower energy consumption, and reduced downtimes. That gives you maximum machine availability, consistent quality and rapid help in a service case.

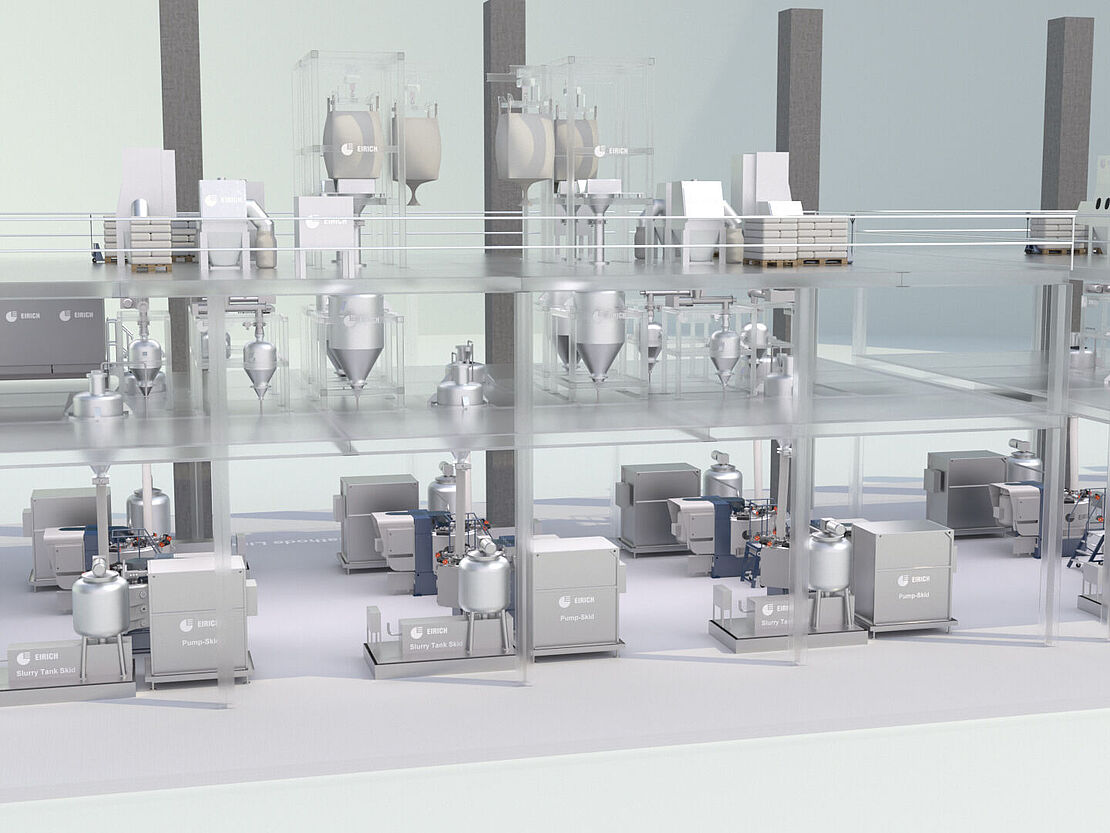

Systems manufacturing - the complete "one-stop" solution

Get advice from one of our experts.

Use the contact form to tell us about your preparation requirements. We look forward to your inquiry.