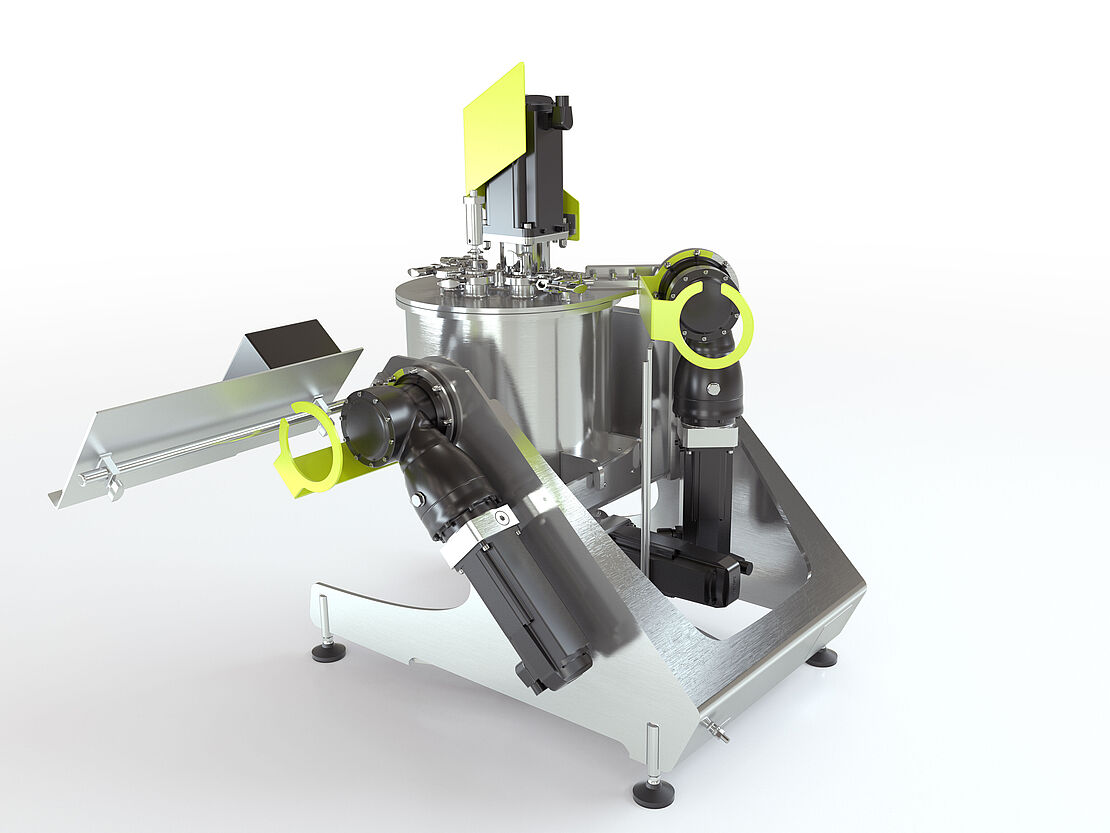

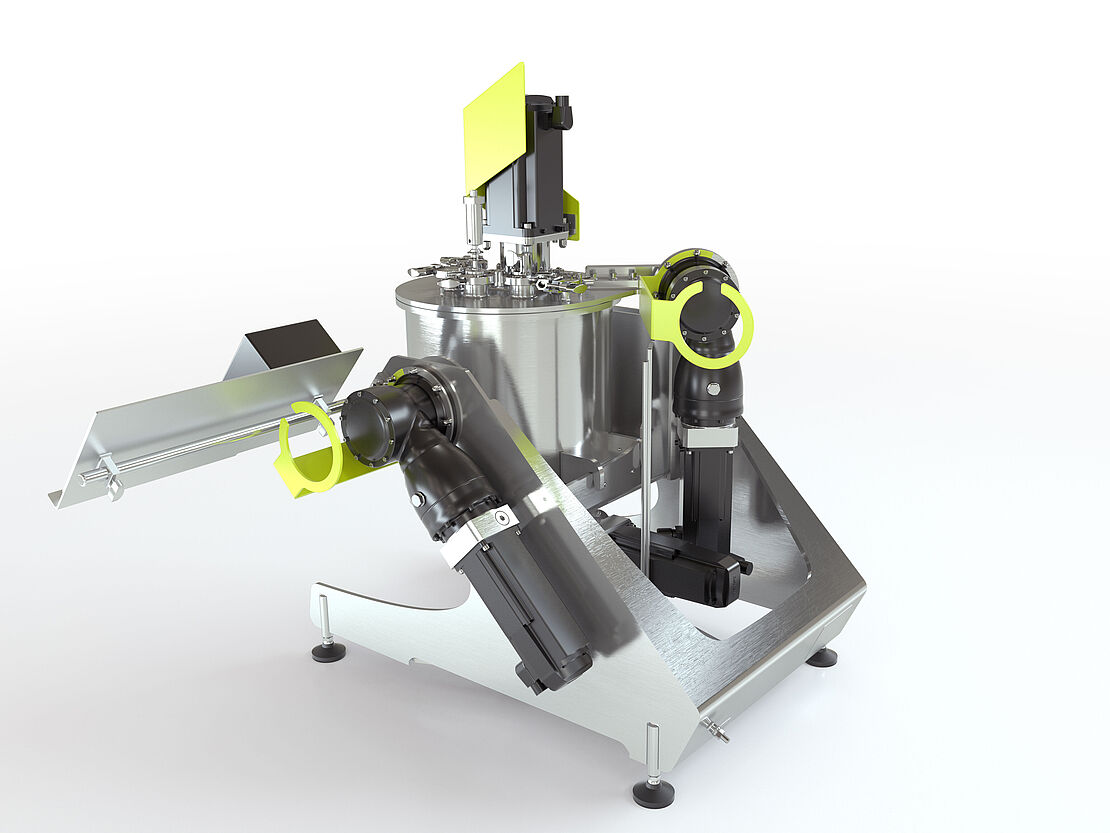

New CleanLine C5

Groundbreaking process technology meets hygienic design

One machine - many options. Don't make your lab unnecessarily full and expensive with a variety of lab machines.

The C5 is the universal one-pot machine that combines an entire development lab in one.

Due to the unique mixing principle, all process operations such as mixing, deagglomerating,

dispersing, granulating, coating, kneading, and drying and many more are possible with a single machine.

Effective cleaning

Thanks to optimized accessibility, smooth surfaces and selected components, the C5 can be cleaned effectively and reproducibly.

Ergonomic and quick handling

The product contacted components (mixing tools, seals, scrapers, mixing vessels) can be assembled and disassembled in the twinkling of an eye.

Extra flexible

Simple change of mixing tools and parameter adaption allows flexible variation of different production and preparation techniques.

Technical features

- Effective volume: 1.6 to 5.0 liters

- One-piece welded mixing tool, selectable in various geometries, with tool speeds from 0.6 m/s to 27 m/s

- Removable mixing vessel for ergonomic working and simple cleaning

- Touching wall scraper to avoid product adhesion

- Full stainless steel, high surface quality Ra < 0.8 μm

- Excellent scalability due to consistent geometrical ratios

in the C-series

Modular extendable features

Sensitive processes can be regulated and controlled by smart extensions to the machine.

- Temperature control via double jacket or radiation heating

- Vacuum version for extended process control (degassing, vacuum evaporation cooling, vacuum contact drying)

- ATEX version

- Visual process monitoring by camera system

- Product temperature measurement

- FDA certifi cates and 3.1 certifi cates according to EN10204

- Accessories (funnel, fi lter, pressure sensor)

- Different materials for scraper blades

- Laboratory tables for ergonomic working

- Mixing vessel seal with sealing air

Application

- Gentle to aggressive and deagglomerating mixing depending on the mixing tool speed and type

- Agglomeration and granulation with controlled variation of granule properties such as size distribution and density by adjusting the shear forces - from microgranules up to 5mm diameter

- Temperature controlled by double-jacket design e.g. for melt granulation or temperaturesensitive products

- Kneading and subsequent suspending with good material circulation and complete deagglomeration in both process steps