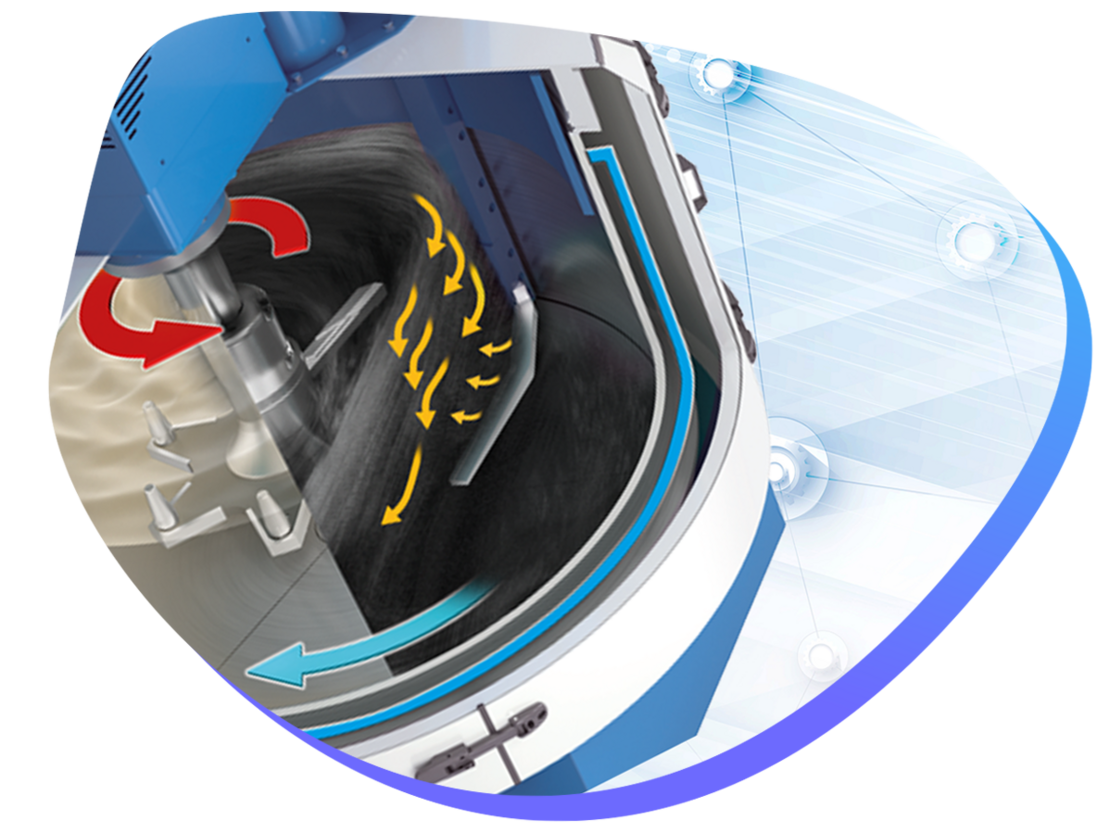

In its MixSolver® variant, the Eirich intensive mixer is also able to process powder mixes that are difficult to mix. After the powders are mixed in the first step, solvents are added gradually until highly plastic compounds and then suspensions are produced – all in a single machine and with just one mixing tool. This applies to cathode materials just as much as to anode materials. Starting from the process of dry mixing, the MixSolver® mixes and functionalizes at the same time. The improved mixing quality improves homogeneity of the electrodes and delivers improved cell performance thanks to the optimized network structure of the conductive additives.