With the different features of the new generation, we now offer exactly the solution that will take you forward.

Advantages of the QualiMaster AT1 inline tester:

- Modular design,so features can be added at any time

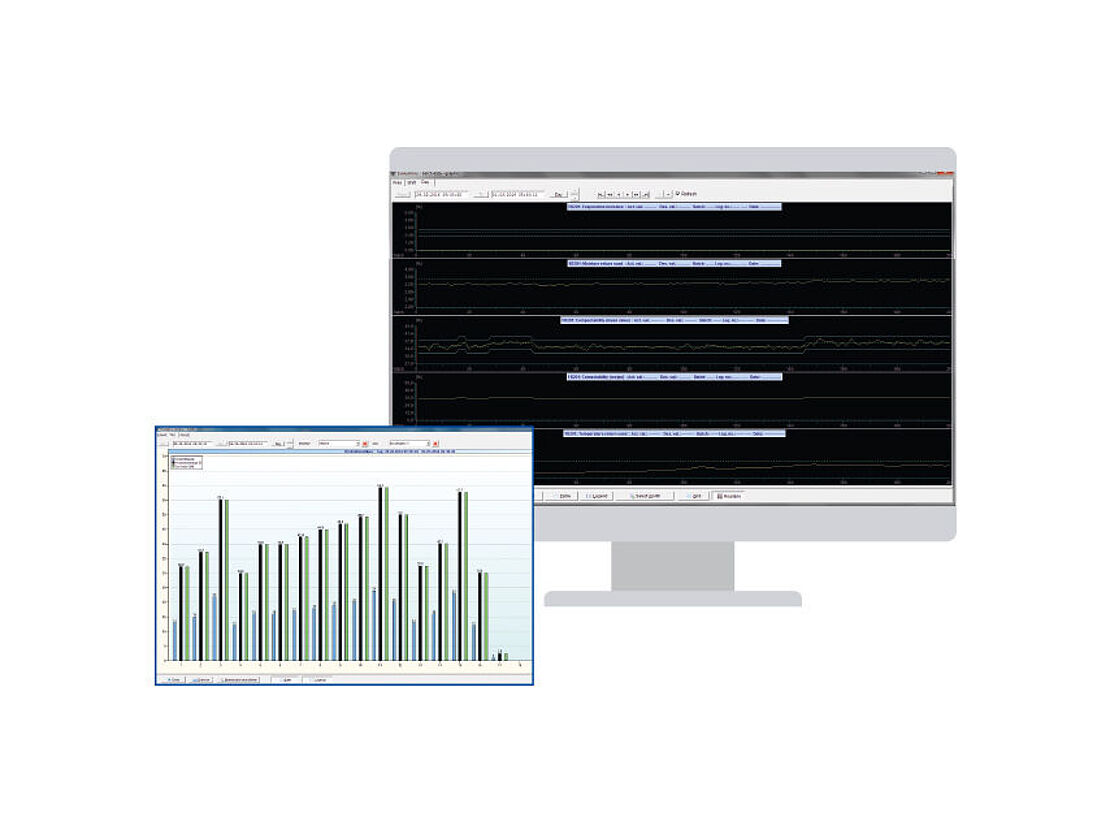

- Web interface with integrated process data visualization

- Eirich ProView for viewing of data on portable terminals

- New measuring options (springback, temperature, gas permeability, deformability)

- Platform-independent communication via OPC UA

- Robust design for demanding conditions

- Reduced measuring time for stable process control

Your benefits:

Less rejects, reproducible quality, stable processes, dimensionally stable castings, less rework and a uniform production

The QualiMaster AT1 Eco is supplied with a web interface and the innovative process data visualization ProView. Our base model measures and logs up to three values per batch on the compactibility of the molding material.

This gives you the possibility of rapidly spotting trends in the development of compactibility. As each batch is sampled, influence can be exerted quickly – either manually or automatically, directly on the next batch.

With increasing quality requirements, you simply retrofit your QualiMaster AT1 Eco with further testing equipment for temperature, springback, gas permeability, shear strength and deformability.

Thinking of renting the QualiMaster AT1 as a standalone unit?

No problem – we shall make it possible.

Whether you are interested in a new Eirich molding material preparation system with QualiMaster quality system or simply want to replace your inline testing unit, we recommend equipment that measures and controls not only compactibility but also at least shear strength.

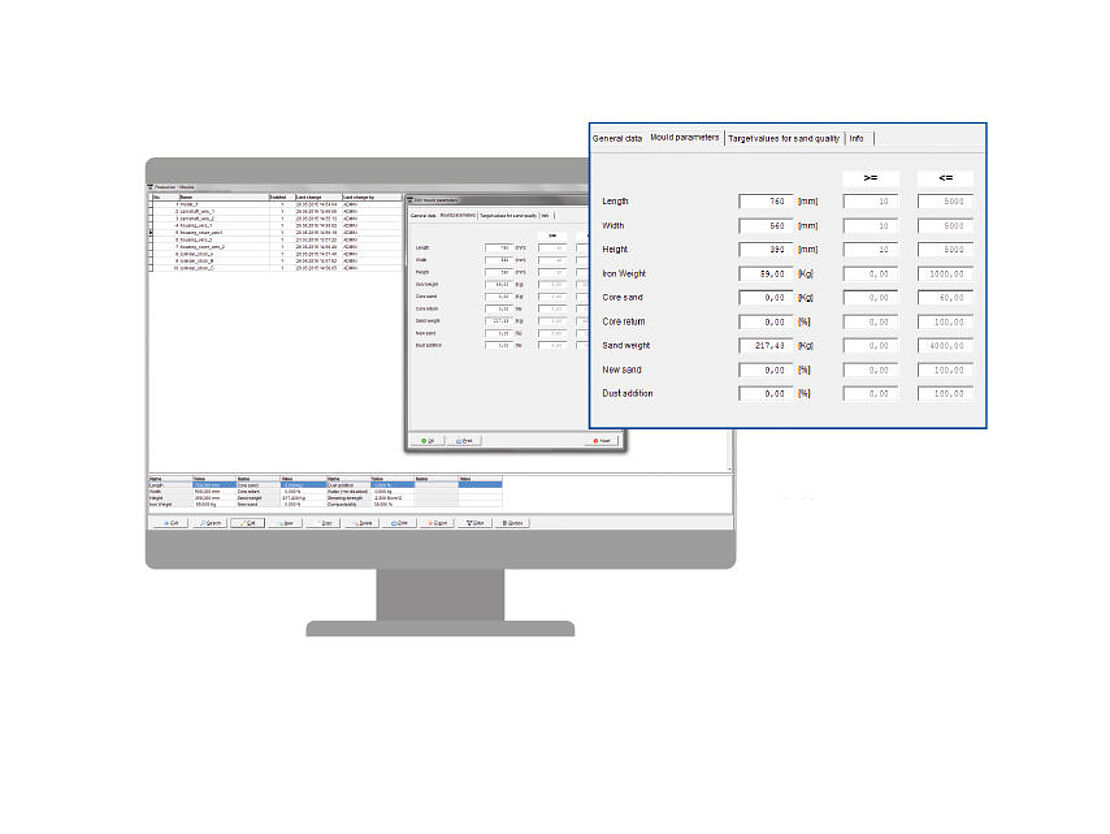

The functional range of the AT1 Profi offers you full control over the key performance features and thus comprehensive quality assurance when preparing your molding material. For both values – compactibility and shear strength - up to three measured values are determined per batch. Via appropriate interfaces, the process values are transmitted to the control system where they are used for automatically correcting the water and the bentonite content.

With the AT1 Profi you control the major influencing variables on your molding material and thus always achieve optimum and constant properties in terms of compactibility and strength of the mold.

In conjunction with the advantageous control technology that Eirich offers you, all processes in the molding material cycle are optimally coordinated with each other.

Would you like to add further measuring options to our AT1 Profi?

Just take the next step with us.

If you set store by highest quality, our QualiMaster AT1 ProfiPlus system offers you a high-end solution that equips you optimally for new challenges. Perfect your processes. Be ready for autonomous molding material preparation.

In the full version - as QualiMaster AT1 ProfiPlus - the quality system offers new possibilities in addition to the measurement and control of compactibility and shear strength.

More reliability regarding the correction factor for evaporation is achieved by a second temperature measurement in the inline tester. In addition, the springback effect is measured in per mil. The measured value informs on the springback effect during the molding process. Moreover, the AT1 ProfiPlus measures and logs the gas permeability as a reference value.